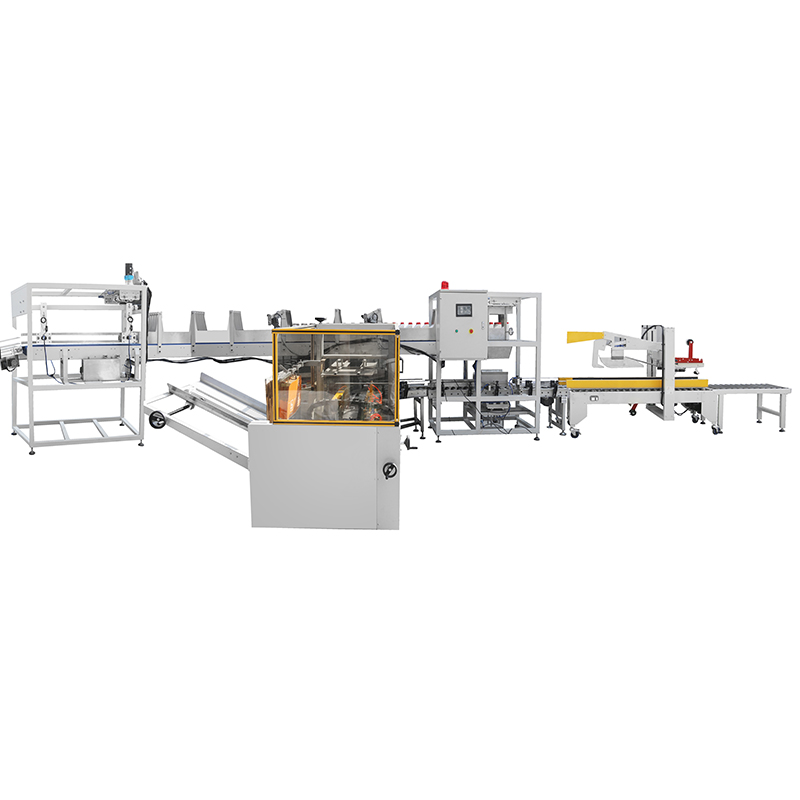

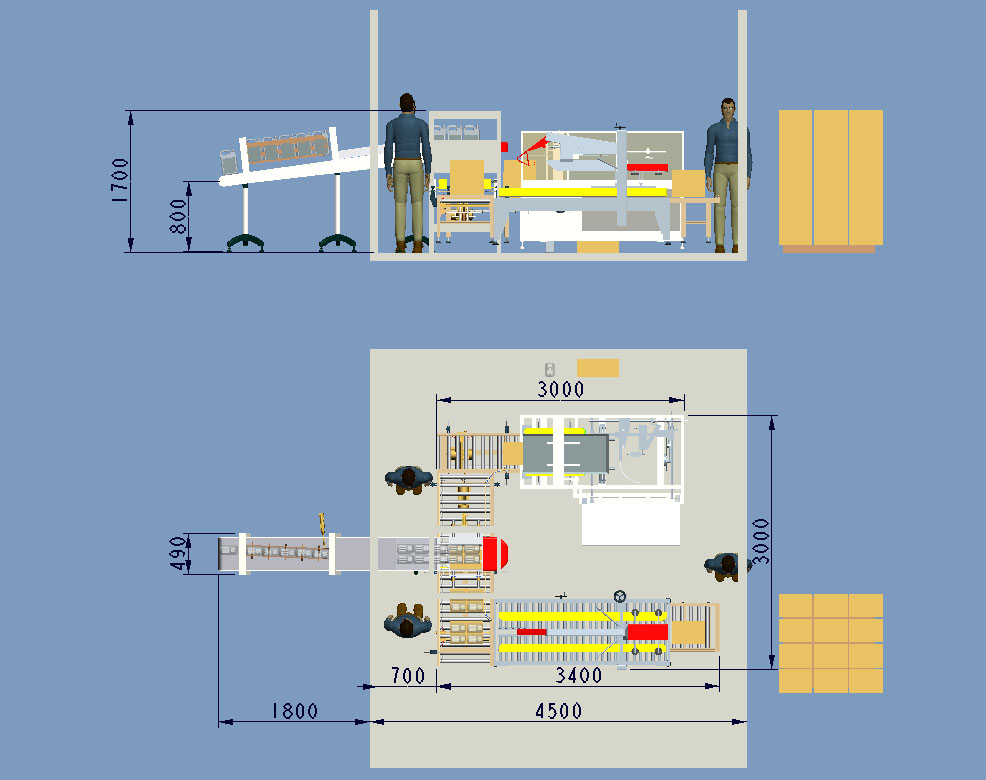

Carton Packing Machine

Automatic Cartoning system

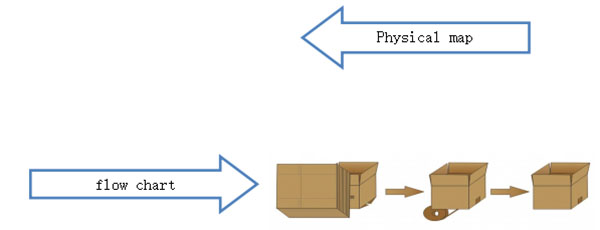

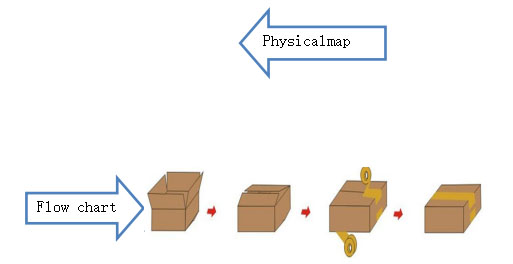

1. The carton open system will open the carton automatically and moulding. Sealing the bottom of the carton then send to the next station.

2. The finished bottle will be arranged according to the carton packing requirement, and get to the carton packing structure.

3. The control center send the signal to the carton packing system, the waiting bottle will dropped into the carton, the carton packing finished.

4. The finished carton will be send to next station for carton sealing machine.

Parameters

| Packing capacity | 6-12 carton/min |

| Platform height | 700mm±50 |

| Voltage | 220V 50HZ |

| Air source | 6-8KG/CM2 |

| Tape size | 48-75mm |

| Weight | 450KG |

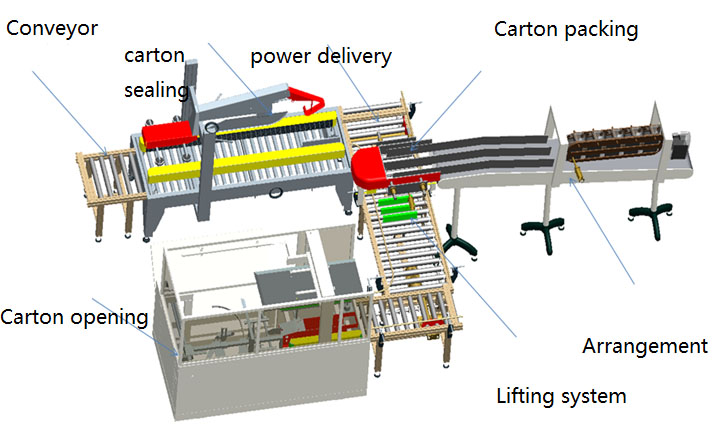

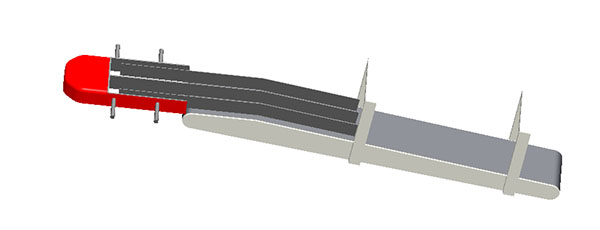

Carton open

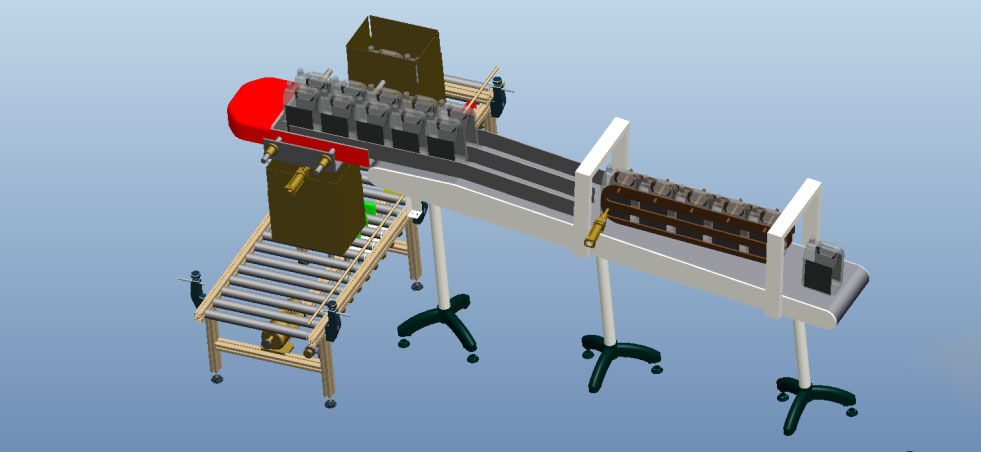

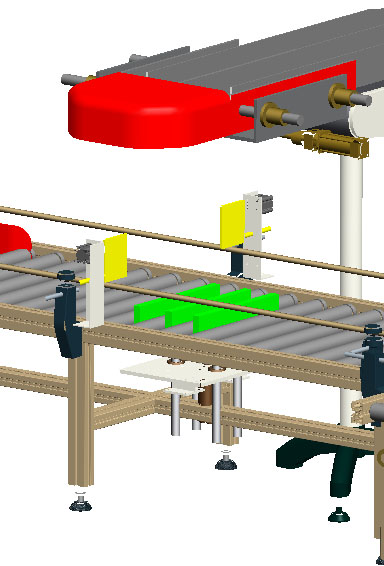

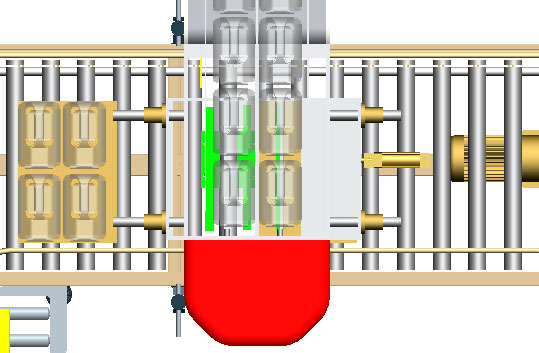

Carton filling system

A: Finished Bottle arrangement

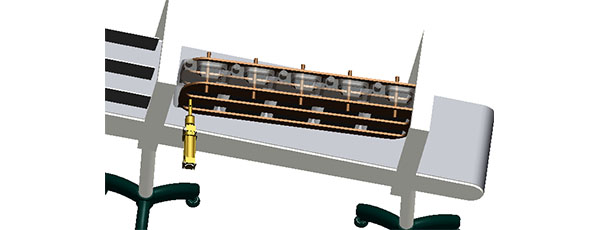

B. Chain plate Conveyor

C. Carton packing structure

D. Finished bottle dropped into the carton part

Carton sealing machine

Parameters

| Sealing Speed | 10-20carton/min |

| Carton size | customized |

| Platform height | 700mm±50 |

| Machine size | L 1730*W910*H1570 |

| Voltage | 220V 50HZ |

| Air source | 5-6KG/CM2 |

Conveyor

Use for connect with machines.

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service