Automatic 6 nozzles Lube Oil Filling Line

Filling machine

This machine is used to fill various liquid products, like oil, beverage, and chemicals etc as long as its liquid. It adopts piston pump filling with servo motor driven which is more accurate and easy to adjust the volume.

Parameter

|

Program |

Lube oil filling line |

|

Filling head |

2, 4, 6, 8, 10, 12, 16 etc(optional according to speed) |

|

Filling volume |

1-5000ml etc(customized) |

|

Filling speed |

200-6000bph |

|

Filling precision |

≤±1% |

|

Power supply |

110V/220V/380V/450V etc(customized) 50/60HZ |

|

Power supply |

≤1.5kw |

|

Air pressure |

0.6-0.8MPa |

|

Net weight |

450kg |

Spindle capping machine

Features

'one motor controls one capping wheel', which can ensure the machine to work stably and keep consistent torque under long term working condition.

Easy to operate.

Mitsubishi PLC and touch screen control, easy to operate.

The gripping belts can be adjusted separately to coordinate with different bottles.

If equipped with guidance device, the machine can cap the pump caps.

Rulers on every adjusting parts to make the adjustment "visible".

The torque limiter is optional to make sure the consistent torque.

The up-down motor is optional to make the machine go up and down automatically.

Aluminum foil induction sealing machine

Features

Easy to use microprocessor controls.

High efficiency, low power consumption and long service life.

Height of sealing line adjustable to accept wide range of bottle heights.

Electric current overload, voltage overload and output overload protection.

Modular component design minimizes maintenance and increased reliability.

Whole stainless steel construction for using in harsh environment and easy for clean and maintenance.

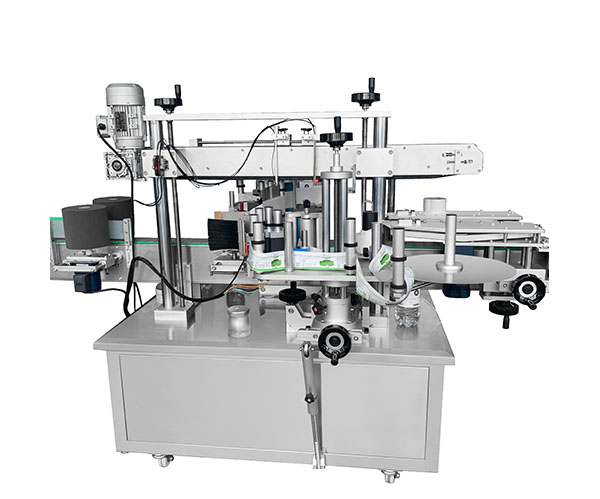

Double side labeling machine

This double side labelingmachine is used to label both flat or square bottles and round bottles. It is economical, and easy to operate, equipped with HMI touch screen & PLC Control System. Built in microchip makes fast and easy adjustment and changeover.

Specifications

| Speed | 20-100bpm( related to product and labels) |

| Bottle size | 30mm≤width≤120mm;20≤height≤400mm |

| Label size | 15≤width≤200mm,20≤length≤300mm |

| Labeling issuing speed | ≤30m/min |

| Accuracy(excluding container and label' s error ) | ±1mm (excluding container and label's error ) |

| Labels materials | Self-sticker, not transparent (if transparent, it needs some extra device) |

| Inner diameter of label roll | 76mm |

| Outer diameter of label roll | Within 300mm |

| Power | 500W |

| Electricity | AC220V 50/60Hz single-phase |

| Dimension | 2200×1100×1500mm |

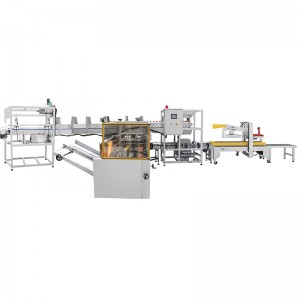

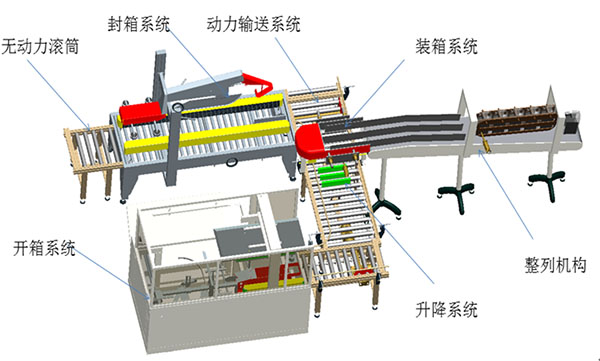

Carton packing machine

1. The carton open system will open the carton automatically and moulding. Sealing the bottom of the carton then send to the next station.

2. The finished bottle will be arranged according to the carton packing requirement ,and get to the carton packing structure.

3. The control center send the signal to the carton packing system, the waiting bottle will dropped into the carton, the carton packing finished.

4. The finished carton will be send to next station for carton sealing machine.

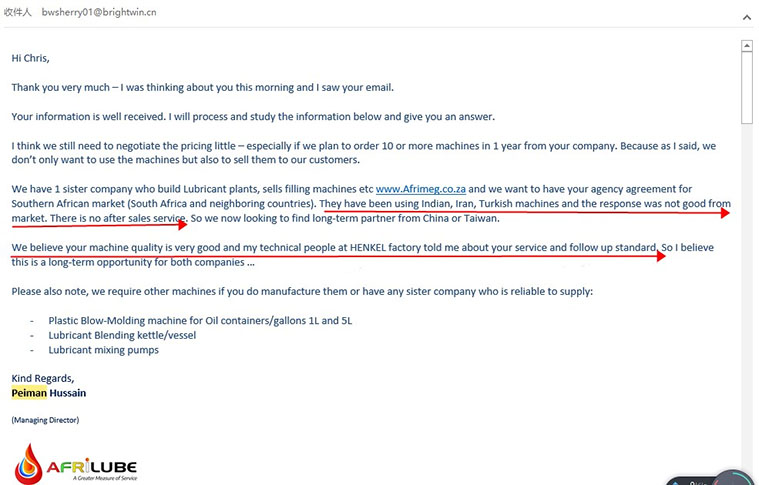

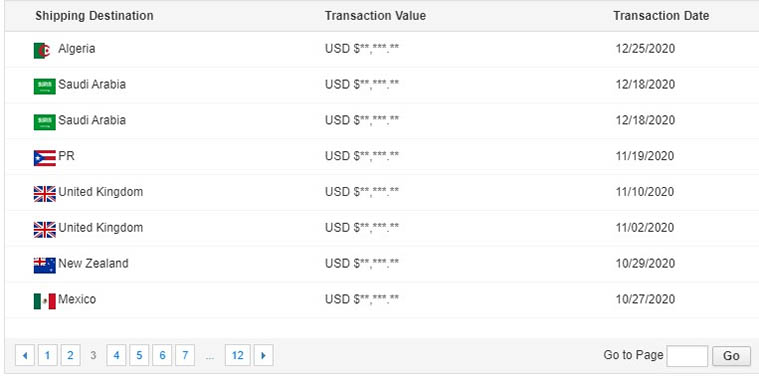

1. Offer professional operation manual

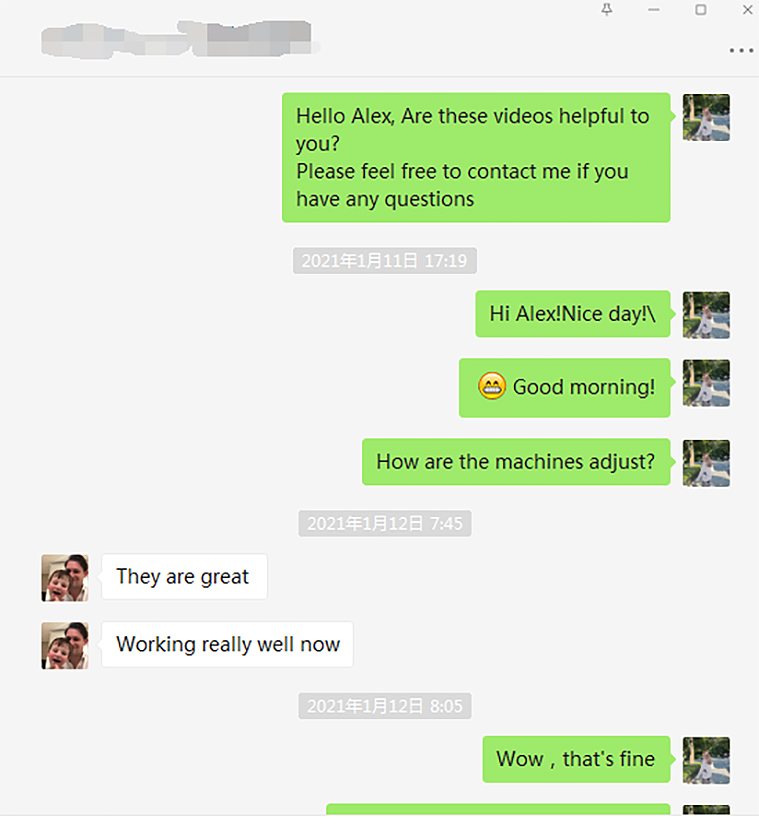

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service